Reference Projects

The following reference list gives a couple of examples of responsibilities and deliveries in past projects.

For more information, questions and discussions, please contact us at info@skeppsprojekt.se

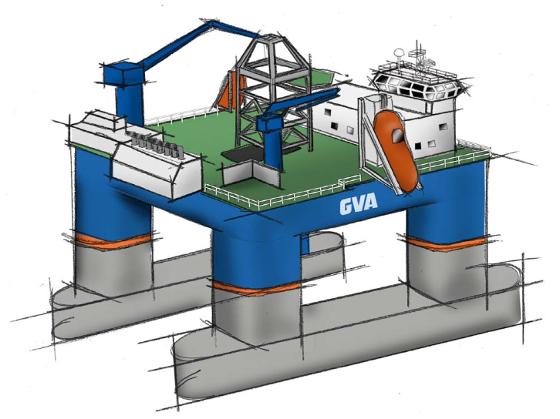

2018 - 2020

Chevron – Anchor Project, General Arrangement. Marine Outfitting and Machinery system

Supporting an ongoing semi-submersible hull project in Houston, Texas, USA. Area Lead for the following project disciplines, General Arrangement, Marine Outfitting. Coordination with Client at GVA Office in Houston. Developed General Arrangement, Marine Outfitting and some Machinery and Utility System documents. Communication over video conference meetings with client, GVA Houston office and on occasion worked in the project office in Houston.

2016 - 2018

BP - MadDog Phase II Project (Argos), Engineering support

Supporting detail engineering in the semisubmersible project BP MadDog II in Houston, Texas, USA and Samsung Shipyard at Geoje Island, South Korea. Supporting the following project disciplines, General Arrangement, Marine Outfitting. Coordination with Client at GVA Office in Houston and at Shipyard in Korea.

2014 - 2016

BP - MadDog Phase II Project, General Engineering

Working from Houston, Texas, USA. Area Lead for the following project disciplines, General Arrangement, Marine Outfitting and Architecture. Coordination with Client at GVA Office in Houston. Held weekly video conference meetings with client, GVA Houston office and GVA Gothenburg office.

2013

Statoil, Cat A - Pre-Feasibility study, Project Management

Leading the successful technical work to win the Pre Feasibility study for the next generation of Light Well Intervention (LWI) Unit.

2012 - 2014

Heerema, SSCV Sleipnir - Heavy lift vessel

Technical sponsor to the disciplines General Arrangement, Weight Management, Technical Safety and Marine Outfitting in the Feasibility study, Pre-FEED and FEED project.

SSCV Sleipnir has the capacity of lifting 20000 tonnes in a tandem lift. After its completion in 2019, SSCV Sleipnir succeeded Heerema's earlier SSCV Thialf as the largest crane vessel in the world.

2011 - 2012

Chevron - Jack & St. Malo, Procurement

Responsible for the following procured packages in the project: Watertight Doors, Elevators, Mooring Chain, Mooring Shackles, Chain Closures and Helidecks. As an example, the volumes in the Chain and Shackle packages are about 8000 tonnes of steel and a value of about $35.000.000.

2009 - 2012

Chevron - Jack & St. Malo, Marine Outfitting

Responsible for following discipline in the project: On/Off vessel Mooring Arrangement, Helideck Arrangement, Arrangement of Obstruction lights and fog signals, Towing and Supply boat Arrangements, Life Saving Arrangement, Draught Marks Arrangement, Escape Route plans, Arrangement of Internal/External Access platforms, Arrangement of Internal/External Ladders and Stairs, Arrangement of Watertight/Weather tight Doors and Hatches, Arrangement of Hatches and Manhole Covers, Arrangement of Personnel and material handling lift.

2008 - 2009

MacGREGOR, Ship to Ship transfer system TAVTS

Task and responsibilities. Strength analysis and analysis report of Ship to Ship transfer system for US Navy Sealift Command. ABS class. The transfer system will make it possible to transfer A1 Abraham Tanks, Trucks, landing crafts etc between two ships travelling on parallel course at four knots in severe weather conditions. The transfer system consists of a foldable side ramp on the Landing ship, dynamically maneuvered and one fixed side ramp on the US Navy Sealift Command ship.

2005 - 2007

Samsung Heavy Industries, Top side Modules

Strength analysis and analysis report of five Deep Drill Ship Topside equipment projects. 230 m Stena Drillmax and Stena DrillMax II (DNV), Mosvold Deep Drillship (10000 ft) ABS Class, TPM Deep Drillship (10000 ft) ABS Class, Petrobras Deep Drillship (10000 ft) ABS Class. Strength analysis of topside modules/equipment like Mud Module, Riser Storage, Pedestal Cranes, Weld test area etc. Analysis of lifting points, fatigue calculation, blast calculation, dropped object calculation.

2007

MacGREGOR, Passenger Towers and Gangways

Strength analysis and analysis report of steel structure for passenger towers and gangways for Color Line Larvik and Kristiansand Harbour facilities.

2006

SCR Converter system Type 49 HS and 9HS

Project Manager for three conversion projects to equip Scandlines M/S Aurora, M/S Tycho Brahe and M/S Hamlet with SCR Converter system for NOx cleaning of exhaust gas from Main engine and Auxiliary engine. The work assignment included system arrangement document, design, strength analysis, construction drawings, procurement, manufacturing inspections, FAT test, Management of PLC control system, installation at shipyard, instruction manual, education of crew and finally certification of system. Lloyd’s Class.

2005

Senitec AB, Bilge/sludge water separator

Strength analysis and analysis report of bilge/sludge water separator steel structure for M/S Finnfellow, M/S Finneagle, M/S Finnclipper (AESA NB-78, NB-79, NB-80).

2005

Munters AB, SCR Converter system

Project to equip Shipyard Aker Finnyards NB 448, 449, 450 with SCR Converter system for NOx cleaning of exhaust gas from Main engine and Auxiliary engine. The work assignment included system arrangement document, design, strength analysis, construction drawings, manufacturing inspections, FAT test and instruction manual. DNV Class.

2005

Munters AB, SCR Converter system

Project to equip Shipyard Aker Langsten NB 209 and NB 210 with SCR Converter system for NOx cleaning of exhaust gas from Main engine and Auxiliary engine. The work assignment included system arrangement document, design, strength analysis, construction drawings, manufacturing inspections, FAT test and instruction manual. DNV Class.

2005

Grenland Framnaes AS, Pressure vessel on FPSO Alba North

Strength analysis and analysis report of pressure vessel on FPSO Alba North. Working with Ansys Workbench for the analysis.

2005

MacGREGOR, Linkspan - ramp

Strength analysis, analysis report, design drawings of steel structure for Link span/ramp for the Port of Immingham. Largest link span in the world. Much of the work also concerned the highly stressed link span bearings. Development of plan for maintenance of bearing system. Lloyd's Class.

2005

MacGREGOR, Ro-Ro Equipment - Liftable cardeck

Strength analysis and analysis report of Liftable cardeck for Shipyard Hyundai NB 1694, NB 1695 - PCTC 6000 units. A car carrier designed to carry 6000 cars. DNV Class.

2003

Munters AB, SCR Converter system Type 157 V & 49 VS

Conversion project to equip Viking Line, M/S Cinderella with SCR Converter system for NOx cleaning of exhaust gas from Main engine and Auxiliary engine. The work assignment included system arrangement document, design, strength analysis, construction drawings, manufacturing inspections, FAT test, installation onboard, instruction manual, education of crew and finally certification of system. By that time certified by Swedish Maritime Administration as the cleanest ship in the world .

2003

Tärntank, Sailing Yacht Marianne

Supporting HVAC System design in the Project.

2002

Munters AB, SCR Converter system Type 196 V

Project to equip Shipyard Volharding NB 528-529 - Balticborg och Bothniaborg with SCR Converter system for NOx cleaning of exhaust gas from Main engine. The work assignment included system arrangement document, design, strength analysis, construction drawings, manufacturing inspections, FAT test and instruction manual.

2000

ABB, SCR Converter system Type 143, 30

Project to equip Shipyard Hyundai Heavy Industries NB 1392&1393 - Stena Brittanica, Stena Adventurer with SCR Converter system for NOx cleaning of exhaust gas from Main engine and Auxiliary engine. The work assignment included system arrangement document, design, strength analysis, construction drawings, manufacturing inspections, FAT test and instruction manual. Lloyd’s Class.

1999

Kockums, Karlskronavarvet, Multipurpose Vessel, Swedish Coast Guard KBV 201 and KBV 202

System design and Package engineer for major systems as HVAC, Hydraulic system, Fast rescue boat launching and recovery system, firefighting system and oil recovery systems.

1998

ABB, SCR Converter system Type 9, 64, and 80

Project to equip Shipyard Kvaerner Leirvik NB, B&N Viking A/S, Engine Cat 3412, MaK 6M32, MaK 8M32, with SCR Converter system 132VS for NOx cleaning of exhaust gas from Main engine and Auxiliary engine. The work assignment included system arrangement document, design, strength analysis, construction drawings.

1998

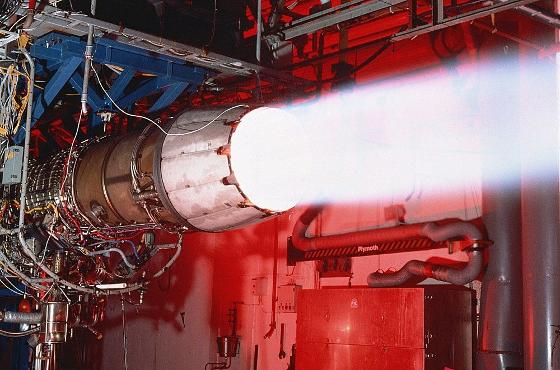

Volvo Aero Corporation

System Design of Test cell no 8 at Volvo Aero Corporation, used for testing aircraft gas turbine engines.

1997

Norsk Hydro AS, Troll C – UMOE/GVA 8000 Semi-Submersible

Strength analysis and analysis report of Steel plating of Troll C Semi-Submersible.

1997

Norsk Hydro AS, Visund – UMOE/GVA 8000 Semi-Submersible

Strength analysis and analysis report of Steel plating of Visund Semi-Submersible.

1996

MacGREGOR, Ro-Ro Equipment

Project to equip US Navy LPD 17 with Submersible Stern ramp. Strength analysis, analysis report, fluid analysis of deployed ramp in severe weather conditions.

1995

MacGREGOR, Ro-Ro Equipment

Project to equip Spanish Navy, LPD 200 with Submersible Stern ramp and Side Door. Strength analysis, analysis report, fluid analysis of deployed Stern Ramp in severe weather conditions. Builder AESA Bazan.

1995

MacGREGOR, Wilhelmsen Line, Ro-Ro Equipment

3D Computer model and Strength Analysis of Jumbo Stern Ramp and ship for Wilhelmsen Line, Taronga. DNV Class. The 3D-model was used in MacGREGOR world wide advertising and exhibitions.

1995

MacGREGOR, Ro-Ro Equipment

Project to equip Shipyard Aesa Puerto Real, NB 77, Baltic Train Ferry, Sweferry with Hoistable Tilting Ramp, Stern Door, Side Doors, Pilot/Bunker Doors. Strength analysis and analysis report. DNV Class.

1993

MacGREGOR, Hurtigruten T.F.D.S. M/S Kong Harald

Work Manager for the Cabin Montage onboard M/S Kong Harald (NB 101) at site on Shipyard Volkswerft in Stralsund, former East Germany.

1993

MacGREGOR, Hurtigruten O.V.D.S. M/S Richard With

Work Manager for the Cabin Montage onboard M/S Richard With (NB 103) at site on Shipyard Volkswerft in Stralsund, former East Germany.

Copyright Nordiska Skeppsprojekt AB